Materials What tiny structures reveal about material properties

Processes in the micrometre range play a crucial role when it comes to forming large sheets of metal into a car roof.

Sheet steel is rarely utilised in the form of a flat plate. After all, the convenient aspect about the material is its flexibility. This is why it is processed by the industry to produce a wide range of different shapes. Engineers collaborating in the Materials Chain network at University Alliance Ruhr (UA Ruhr) explore what happens during the forming process in the size range smaller than one millimetre. More specifically, they develop models based on the microstructure of a material that are capable of predicting the respective material’s behaviour during forming. Will the material be particularly flexible? How exactly can it be formed? Can it be formed evenly, or does its thickness vary in different spots?

The UA-Ruhr flagship program Materials Chain specialises in multiscale modelling. Researchers from Bochum, Dortmund and Duisburg-Essen study the entire process, from the development of new materials in the nano range to manufacturing technology and application. To this end, they combine experimental methods with computer simulations.

From atom to finished component

The material-forming project is a collaboration between Prof Dr Alexander Hartmaier from the Interdisciplinary Center for Advanced Materials Simulation (ICAMS) in Bochum, Prof Dr Jörg Schröder from the Institute of Mechanics in Duisburg-Essen and Prof Dr Dr Erman Tekkaya from the Institute of Forming Technology and Lightweight Components in Dortmund. Currently, the microstructure of a material is not considered in existing models that describe the processes during material forming. “This is despite the fact that they greatly affect a material’s macroscopic properties,” says Dr Napat Vajragupta, engineer at ICAMS in Bochum.

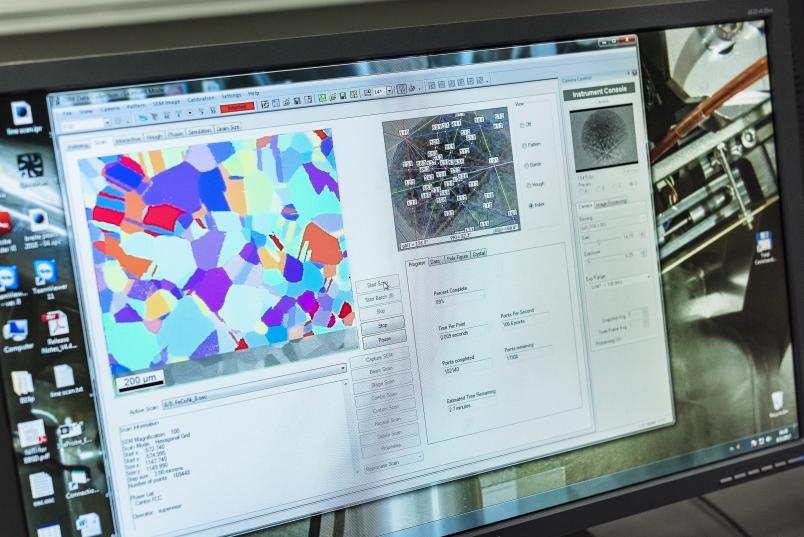

The term microstructure refers to a material’s composition on the micrometre scale. For example, the variety of steel utilised in the automotive industry is not evenly textured. Viewing a 100 by 100 micrometre section under the microscope, a grainy structure is rendered visible, and the grain sizes may vary. Depending on the material, several types of grains may occur: they differ in terms of their crystal structure, i.e. the spatial arrangement of atoms. Other properties characterising the material include the proportion and distribution of different grain types.

Two-pronged predictions

But why is it important to understand the microstructure of a material? What are the advantages when compared to currently existing models that predict how the material will behave during forming? Models that don’t take the microstructure into consideration have to be painstakingly fed with parameters for each new material or microstructure that has been newly developed. This is supposed to change thanks to the new models developed by the Materials Chain team.

In addition, the project aims at creating a process with two-pronged functionality. Based on a material’s microstructure, the researchers intend to predict its macroscopic properties, i.e. its behaviour during forming. They also want it to facilitate the development of customised materials for specific applications. “Once we identified the properties a material is supposed to have, our models should be able to predict the microstructure required for this purpose,” explains Vajragupta.

The first step in the development of such models are experimental tests that enable researchers to characterise the microstructure of a specific material, for example that of dual-phase steel. It contains two different types of grains with different crystal structures. The engineers record the proportion and distribution of both types of grain as well as the number of grains of each size. They also test how the steel reacts to external pressure. To this end, they make a dent in the surface using a tiny point, and monitor in what way the crystal lattice deforms depending on the direction from which the lateral pressure is applied to the crystal structure.

Today, all this is just a click away.

Napat Vajragupta

Based on the thus gathered information, the researchers then compile a virtual representation of the microstructure at the computer. “Today, all this is just a click away,” explains Napat Vajragupta. “Complicated algorithms are being executed in the background, of course; but we have developed this process specifically to make it easy to use.” The platform deployed by the engineers for designing the microstructure representation is continuously being optimised to ensure that the virtual models provide an increasingly better description of the real microstructure.

Once the microstructure representation has been completed, the material has to undergo a virtual test: the researchers simulate the way a material with this particular structure would behave if subjected to different external forces; for example, what happens if it is compressed or pulled apart, or if it is subjected to shear forces. This knowledge can be useful to find out if that material would be suitable for a specific application – whether it can be formed into a car roof, for instance. With the aid of the model, the researchers wish to gain a better understanding of the way in which the microstructure affects the properties of a material.

When simulating forming processes, the engineers pay particular attention to the way the material deforms in different spatial directions, and to the spots where springback occurs. These properties, too, are linked to the microstructure. Depending on the direction from which lateral pressure is applied to the crystal structure, the material deforms more or less strongly.

The prediction model is currently working quite well for simple stress scenarios, e.g. if the user assumes that the material will be subjected to shear forces alone. However, when steel sheet is processed in the industry, the deformation process is much more complex: the material is affected by forces other than just shear conditions; rather, it is simultaneously pulled apart or compressed, and the stress changes all the time. The teams at the universities in Dortmund and Duisburg-Essen are designing models and processes capable of representing such complex stress and strain scenarios in experiments as well as in computer simulations.