Plasmas reach temperatures of several thousand degrees. This energy can be used for the environmentally friendly production of steel and hydrogen.

Physics

In the Eye of the Plasma Storm

Researchers hope to use plasmas to make the production of hydrogen and steel more environmentally friendly. The key to this is a tornado that they generate in a lab.

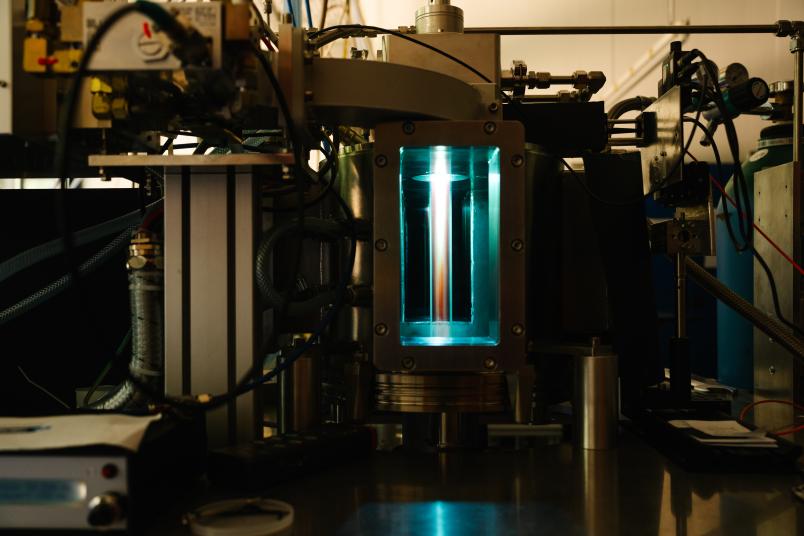

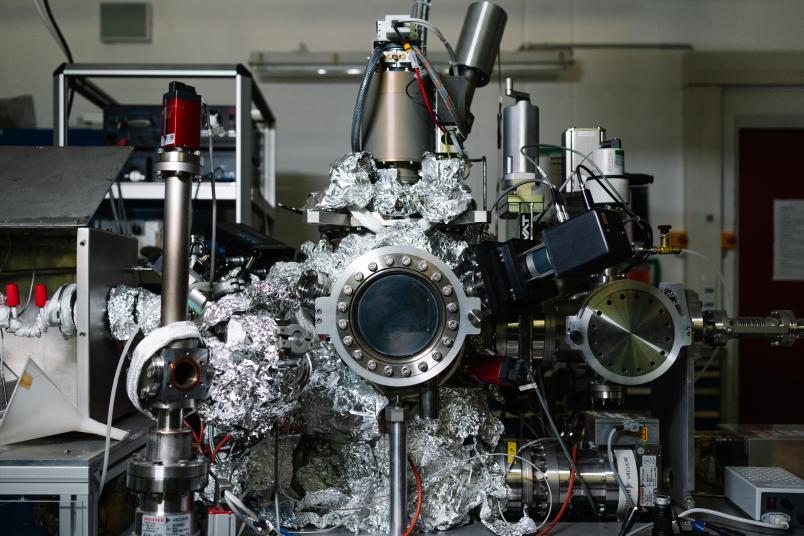

There is a storm brewing in the physics lab in Bochum, and talk of tornados and temperatures of thousands of degrees Celsius. Yet this has nothing to do with the climate: The labs house all manner of metallic devices with small windows that show colorful lights. These glowing objects within the reactors – which conveniently fit on a table – are plasmas. And they can do just about anything: Plasma can be used to sterilize surgical instruments, brighten displays, or facilitate energy-intensive industrial processes.

Plasmas

Plasmas

At Ruhr University Bochum, the team in the Department of Experimental Physics II, especially Physics of Reactive Plasmas, is working on the climate-friendly production of hydrogen that can then be used to produce green steel through the use of plasmas.

Environmentally friendly hydrogen production

Gray hydrogen is obtained through steam reforming of natural gas containing methane, which results in high carbon dioxide (CO2) emissions. A more environmentally friendly method involves producing hydrogen by splitting water with electrical energy from renewable sources. “This type of production of green hydrogen, as we call it, is inefficient, however,” says Professor Achim von Keudell, chair of the Department of Experimental Physics II in Bochum. This is why his group is focusing on something in the middle: turquoise hydrogen. Like gray hydrogen, this is acquired from methane, but with a different chemical process: methane pyrolysis. “The methane is heated to the point that it splits into hydrogen and carbon,” von Keudell explains. Carbon accumulates as a solid, not as gaseous carbon dioxide as is the case with gray hydrogen.

Jonas Thiel (left) and Achim von Keudell (right) are optimizing the tornado plasma technology for various applications.

“Not all carbon is the same,” von Keudell continues. “If it’s sitting there as a plain briquet, all you can do is ignite it or put it back in the mine for storage. But there are also high-quality carbon nanoparticles that serve as the basis for industrial processes.” These are found in various products, from printer toner to car tires.

That makes this method of economic interest.

Carbon nanoparticles are a byproduct of the production of turquoise hydrogen via plasmas. “That makes this method of economic interest,” von Keudell notes. In his team, Dr. Simon Kreuznacht developed a plasma for this process during his doctorate.

Plasma tornado prevents reactors from melting

Plasmas can reach temperatures of thousands of degrees, and it is easy to reach the temperatures needed for methane pyrolysis. “You have to make sure the plasma doesn’t overheat to the point that the reactor melts,” says von Keudell. To prevent this, Simon Kreuznacht used a rotating flow: tornado plasma. The gas that plasma is made from is spun around upon being placed in the reactor and then heated up through microwave radiation. This results in a plasma tornado with a hot center of 3,500 to 5,500 degrees Celsius, and a cooler boundary zone, which itself is still around 1,700 degrees Celsius. While pyrolysis takes place in the hot center and creates hydrogen, the temperatures in the outer zone of the tornado are ideal for producing carbon nanoparticles.

But tornado plasma is also useful for other processes, such as the production of green steel. Iron ore serves as the basis for steel production. It is comprised of iron in the form of oxygen-containing iron oxides. To extract iron from this, the ore has to be reduced: Electrons from another substance, known as the reductant, have to be transferred to the iron ore, whereby oxygen is released. Carbon in the form of coke is often used as the reductant. With the oxygen from the iron ore, it forms climate pollutants as waste products, like carbon dioxide or carbon monoxide. However, hydrogen can be used as the reductant instead of coke, with water as the resulting waste product.

High-quality steel with the plasma process

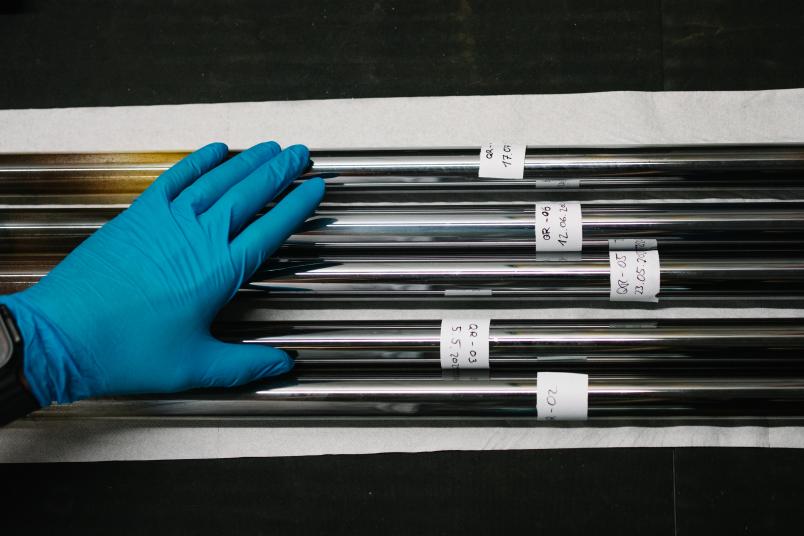

Another crucial ingredient is needed in addition to a well-functioning reductant: a lot of energy. This is where plasma comes in. Doctoral student Jonas Thiel is currently optimizing tornado microwave plasma for steel production. This involves spinning plasma gas containing hydrogen to create another plasma tornado. The iron ore is blown into the center of the tornado as a powder and fed into a quartz pipe. Here, it is excited and heated by microwave radiation so that the hydrogen gas reaches its plasma state. In the center of the plasma tornado, the iron oxide from the powdered iron ore is converted into iron, which is later turned into an alloy with other elements to form steel. Unlike other blast furnaces, the plasma process creates particularly high-quality steel.

When this happens, we have to pause the process and scrub it down.

This process already works in principle. Thiel is now fine tuning it. Numerous aspects of the plasma reactor can be precisely adjusted to influence the reaction occurring inside, which sets the reactor apart from blast furnaces. “Our current challenge is that the quartz pipe containing the plasma gets coated with the resulting metal after a while,” says Thiel. The iron is expelled from the tornado like in a carousel and accumulates on the quartz wall. “When this happens, we have to pause the process and scrub it down”, he explains.

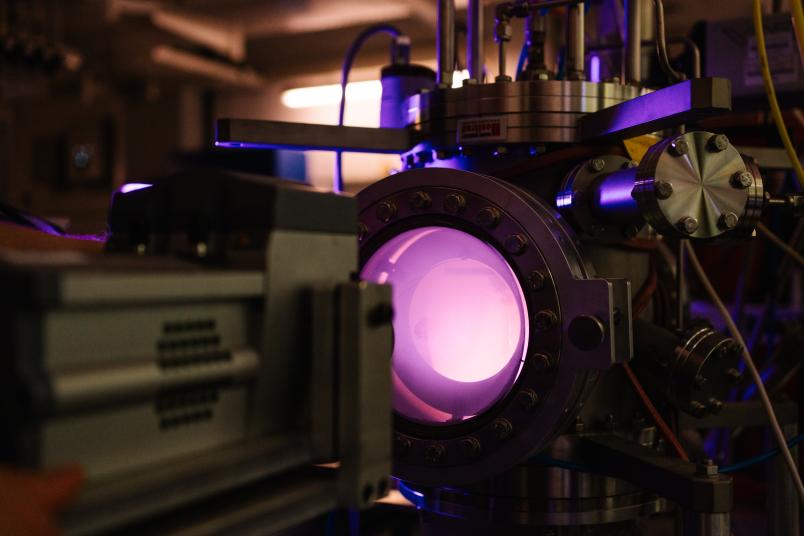

The glow of a plasma reveals something about its composition.

The researchers in Bochum are able to use various measurement processes to visualize the temperature distribution in the plasma reactor, thereby observing the lifecycle of the iron and iron oxide particles in detail. The team can determine where which particles are converted and how the chemical processes depend on the size distribution of the iron ore particles. In the future, they want to test what happens when they treat the iron ore particles in the hydrogen plasma for various lengths of time or in slightly different temperatures, which allows them to approach the ideal conditions for the process.

What the glowing reveals

The colorful glow of the plasma also helps them balance out the results, as it contains a wealth of information. The physicists represent it in the form of a spectrum, which indicates the wavelengths at which the plasma glows, and how intensely. Certain elements or molecules emit light at specific wavelengths, so the spectrum tells researchers which particles are present in the plasma. Thus, the glow is not just decoration in the lab, but a crucial source of information for the further development of processes that could make industrial processes more sustainable.