Chemistry

Inorganic and biocatalysts work together to reduce CO2

In a hybrid cascade, climate-damaging CO2 is turned back into valuable methanol. An international research team has shown how this works.

In order to recover valuable substances from CO2, it must be reduced in many individual steps. If electrocatalysis is used for this, many potentially different potential molecules are formed, which cannot necessarily be used. Biocatalysts, on the other hand, are selective and only produce one product – but they are also very sensitive. An international research team led by Professor Wolfgang Schuhmann from the Center for Electrochemistry at Ruhr-Universität Bochum, Germany, and Dr. Felipe Conzuelo from the Universidade Nova de Lisboa, Portugal, has developed a hybrid catalysis cascade that makes use of the advantages of both processes. The researchers report in the journal “Angewandte Chemie Interational Edition” from December 23, 2024.

Advantages and disadvantages of electrocatalysis and biocatalysis

Methanol is one of the substances that we would like to obtain from climate-damaging CO2. It is often used as a synthesis raw material in the chemical industry. “Many reduction steps are required to produce methanol, as carbon dioxide is the most highly oxidized form of carbon,” explains Wolfgang Schuhmann. Electrocatalysis is able to initiate these steps. However, while it is still selective in the first step, the reaction path then branches out and up to 16 different products are formed, not necessarily methanol. The situation is different with biocatalysts: these natural enzymes catalyze just one reaction and therefore only yield one product. However, they are complicated to handle, very sensitive or require cofactors for the reaction.

Combining both processes

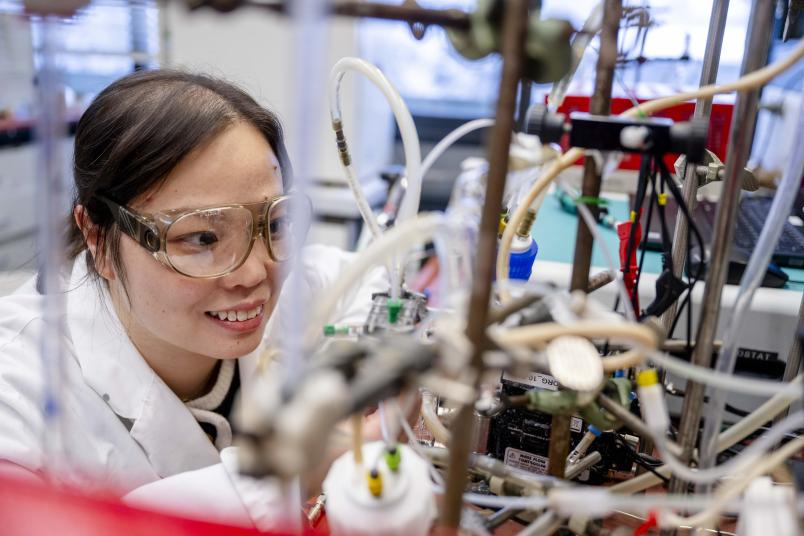

In order to combine the advantages of both processes, the team led by first authors Panpan Wang and Xin Wang married electrocatalysis and biocatalysis. While the first reaction step from CO2 to formate is electrocatalytic, the second and third steps are catalyzed by formaldehyde dehydrogenase and alcohol dehydrogenase. These enzymes require NAD (nicotinamide adenine dinucleotide) as a cofactor, which is consumed by the catalytic reaction and must be regenerated. This regeneration is achieved by a third enzyme. Finally, the valuable substance methanol is produced. “The work proves that such hybrid cascades are in principle feasible and make complex, multi-step reactions selectively possible,” summarizes Wolfgang Schuhmann.