Microbiology

Tiny Beads Preserve Enzymes for Biocatalysis

Plasmas can provide the co-substrate needed for biocatalysis of valuable substances, but are also harmful to enzymes. By attaching enzymes to small beads the enzymes are protected and remain active up to 44 times longer.

Some enzymes, such as the one derived from fungi and investigated in this study, are able to produce valuable substances such as the fragrance (R)-1-phenylethanol. To this end, they convert a less expensive substrate using a co-substrate. A research team from the Department of Biology at Ruhr University Bochum, Germany, came up with the idea of supplying them with this co-substrate using a plasma – a somewhat crazy idea, as plasmas generally have a destructive effect on biomolecules. However, by employing several tricks, the researchers led by Professor Julia Bandow and Dr. Tim Dirks did indeed succeed. They have now refined one of these tricks and thus improved the process: They attach the enzymes to tiny beads in order to hold them in place at the bottom of the reactor, where they are protected from the damaging effects of the plasma. By identifying the most suitable type of bead, they also increased the stability of the enzyme by a factor of 44. They published their findings in the Journal of the Royal Society Interface from October 25, 2023.

Model enzyme from an edible fungus

“In plasma-driven biocatalysis, we intend to use technical plasmas to drive enzymes that use hydrogen peroxide to convert a substrate into a more valuable product,” explains Julia Bandow, Head of the Department of Applied Microbiology. The plasmas – energetically charged gases – produce hydrogen peroxide as well as a variety of reactive species.

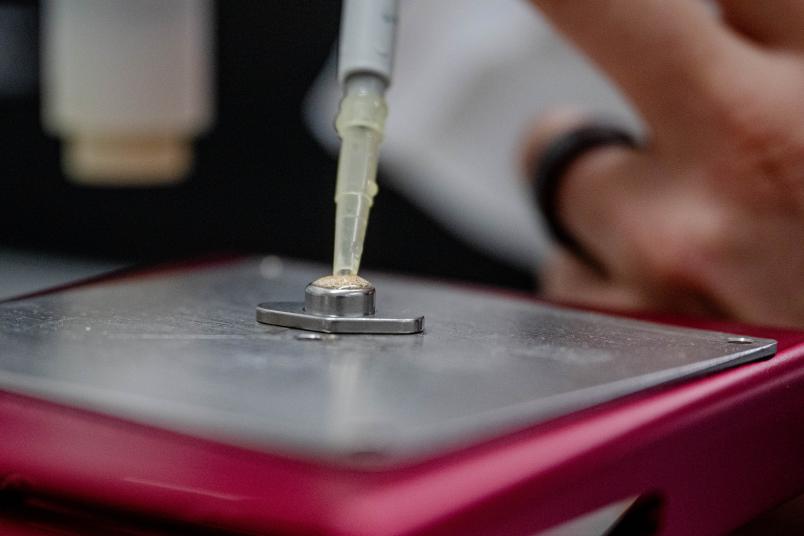

The researchers use the non-specific peroxigenase (AaeUPO) from the edible fungus Agrocybe aegerita as a model enzyme. They showed in initial studies that although it works for plasma-driven biocatalysis, there are some fundamental limitations. “The decisive factor was that the enzymes are sensitive to plasma treatment and are therefore inactivated within a short period of time,” Tim Dirks, lead author of the current study, explains. “To prevent this, we use the method of enzyme immobilization by attaching the enzymes to tiny beads with a porous surface.”

Beads trap the enzymes at the bottom

Due to gravity, these beads lie on the bottom of the sample and the buffer solution above provides a protective zone between the plasma phase at the top and the enzymes. The research team observed at an early stage that the different immobilization methods also led to different survival rates of enzymes. The aim of the current study was therefore to investigate the effects of different immobilization methods on the plasma stability of enzymes using a larger set of enzymes.

Five different enzymes were selected; two of them also convert hydrogen peroxide and three of them don’t require hydrogen peroxide for activity. The researchers tested nine different types of beads, some of which had a resin surface and others a silica surface with or without a polymer coating. After immobilization, the enzymes were treated with plasma for up to five minutes. The researchers then compared their residual activity with untreated controls.

The path to new applications

The beads with resin surfaces showed the best results for all five enzymes. “The amino and epoxy-butyl beads performed best,” says Tim Dirks. In both cases, the enzymes form a strong, covalent bond with the carrier material, which can’t be dissociated. “This type of immobilization appears to limit the mobility of the enzymes, which makes them less susceptible to plasma-induced inactivation,” outlines Tim Dirks. By extending the plasma treatment for the most promising candidates to up to one hour, the team was able to increase the stability of the enzymes under plasma treatment by immobilization up to a factor of 44. “The findings of this study thus pave the way for new applications that aim to combine enzymes with technical plasmas in the future,” the researchers conclude.